- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

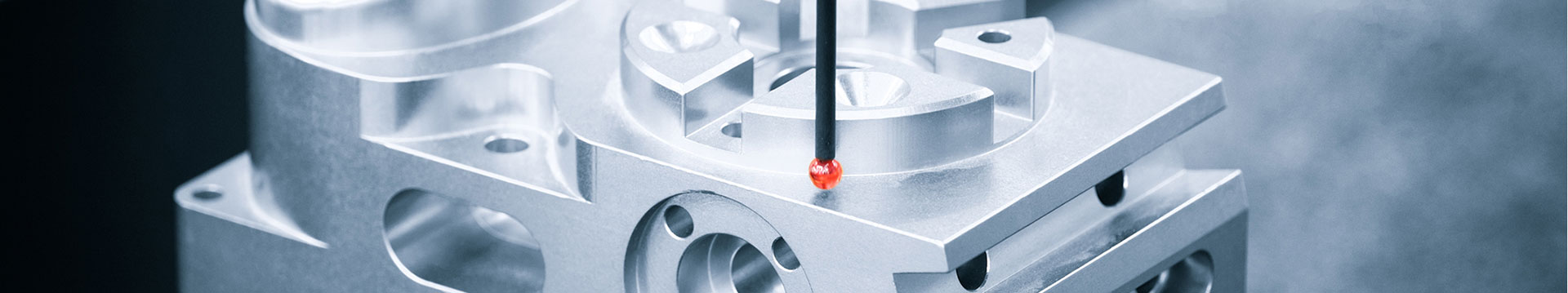

high quality aluminum alloy casting

2022-08-22

Castings have different requirements such as material, size, shape complexity, dimensional accuracy, surface roughness, production batch size, etc., and the most cost-effective casting process needs to be selected. Sand casting, precision casting, die casting and other processes have their advantages and disadvantages.

Sand casting is to make the original sand into a sand core through core making equipment and other equipment, and form a casting mold. The smelted metal liquid is then poured into the casting mold, and the casting is obtained after cooling, solidification and cleaning treatment.

The castings produced by JJ have the characteristics of complex design, difficult process and high precision. We support the application of sand casting, high pressure casting, low pressure casting, gravity casting and other processes. Provide high quality aluminum alloy castings such as condensing boiler heat exchangers, commercial vehicle engine cylinder heads and lightweight gearbox casings, rail transit and high-speed train pump valve casings for customers in thermal energy engineering, automobiles, rail transit, mechanical equipment and other fields.