- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

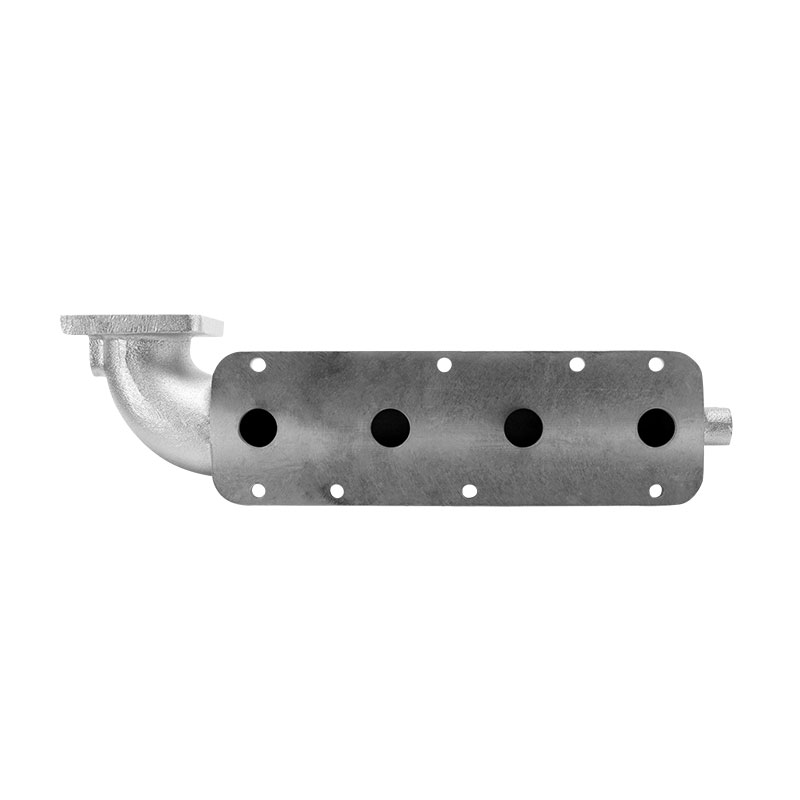

What Are Heat Exchanger Parts and How Do They Impact Heat Transfer Efficiency

2025-12-19

HEC Machinery proudly presents an expert guide on Heat Exchanger Parts, exploring the core components used in heat exchanger systems and why they matter for industrial applications. From tubes to baffles and headers, we’ll uncover what each part does, how it works, and how choosing the right parts impacts performance, efficiency, and long-term reliability in your heat exchanger equipment.

Article Summary

This guide dives into the essential parts of a heat exchanger, detailing their roles, configurations, and impact on performance. Covering practical questions like “What are the key components?”, “How do heat exchanger parts affect efficiency?”, and “Which materials are best suited for specific parts?”, this SEO-optimized article follows Google’s EEAT principles to provide authoritative, experienced insights. You’ll also find helpful diagrams, tables, and FAQs to boost your understanding and decision-making when selecting parts for your industrial or commercial heat exchanger systems.

Table of Contents

- What Are Heat Exchanger Parts?

- Why Is Each Part Important?

- How Do Materials Impact Performance?

- Which Parts Are Critical for Your Application?

- Heat Exchanger Components Overview Table

- FAQs

- Conclusion & Next Steps

What Are Heat Exchanger Parts?

Heat exchanger parts are the collection of core components that make up the internal and external structure of a heat exchanger, facilitating the transfer of thermal energy between two fluids without mixing them. These parts vary based on the type of heat exchanger—shell-and-tube, plate, air-cooled, and others—but typically include tubes, tube sheets, baffles, headers, nozzles, and seals among others.

At HEC Machinery, we manufacture precision Heat Exchanger Parts that are engineered for superior heat transfer performance, built to match a range of industrial applications from condensing boilers to heavy-duty heat exchanging systems.

Why Is Each Part Important?

Understanding the role of each part helps in optimizing heat exchanger efficiency and service life. Major components such as tubes and baffles affect the heat transfer area and fluid turbulence respectively, which directly influence the effectiveness of heat exchange.

- Tubes – Act as the primary surface for heat transfer between fluids.

- Tube Sheets – Support and secure tube bundles while separating flow paths.

- Baffles – Direct fluid flow and increase turbulence to enhance thermal performance.

- Nozzles & Headers – Provide interfaces for fluid inlet/outlet and distribution.

- Pass Partitions – Increase fluid pass count for enhanced efficiency.

How Do Materials Impact Performance?

The material of each heat exchanger part affects corrosion resistance, heat conduction, and durability under various operating conditions. For instance, stainless steel or copper tubes suit corrosive applications, while aluminum castings excel for lightweight yet strong configurations. HEC Machinery’s heat exchanger parts use EN1706/AC43000 alloys optimized for structural precision and thermal performance.

Which Parts Are Critical for Your Application?

Depending on your application—industrial heat recovery, process heating, or HVAC systems—certain parts become more critical:

- High-pressure applications – Tube sheets, expansion joints, and tie rods must resist deformation.

- High-temperature systems – Headers and tubes need compatibility with temperature cycling.

- Space-limited designs – Compact baffles and multi-pass partitions improve performance in smaller footprints.

Heat Exchanger Components Overview Table

| Component | Function | Common Material |

|---|---|---|

| Tubes | Heat transfer surfaces | Stainless Steel, Copper |

| Tube Sheets | Support tube bundle | Carbon Steel, Stainless Steel |

| Baffles | Direct fluid and increase turbulence | Carbon Steel |

| Nozzles & Headers | Fluid distribution | Alloy Steel |

| Pass Partitions | Increase passes for efficiency | Metal Alloys |

Frequently Asked Questions (FAQs)

What defines a quality heat exchanger part?

A quality part provides reliable performance under operating conditions, minimizes leakage, and resists corrosion. Material selection and precision casting or machining both influence quality. HEC Machinery uses certified casting processes to ensure integrity.

Can heat exchanger parts be customized?

Yes. Many manufacturers, including HEC Machinery, offer customization based on design drawings or performance requirements, ensuring parts meet stringent operational standards.

How often should heat exchanger parts be inspected?

Regular inspection intervals depend on usage intensity, but typically annual checks for fouling, corrosion, and leaks ensure optimal performance and early problem detection.

Conclusion & Next Steps

Understanding the roles and interactions of each Heat Exchanger Parts component enables you to make informed choices that improve system efficiency, reduce downtime, and extend service life. With high-quality castings and expert engineering support from HEC Machinery, your heat exchanger projects achieve dependable performance in any industrial setting. Ready to upgrade or customize your heat exchanger parts? Contact us for tailored solutions and competitive quotes that align with your operational needs.