- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

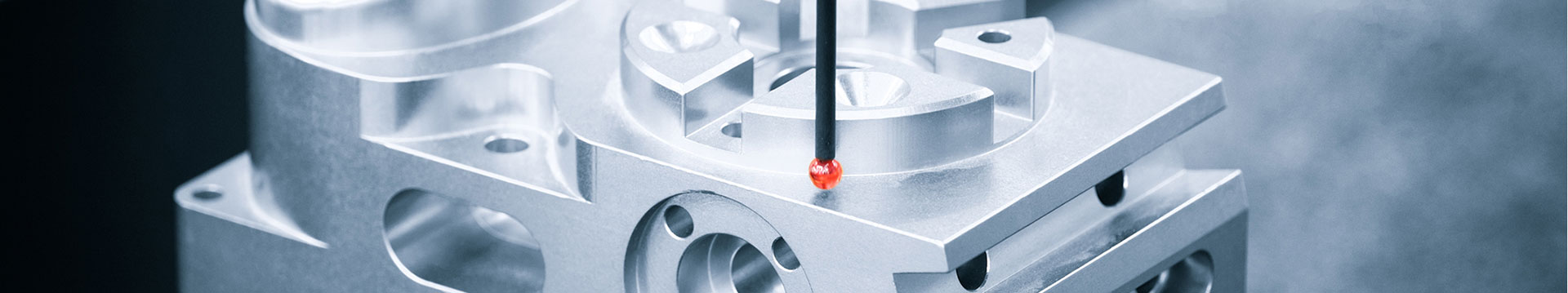

Heat Exchangers Aluminum VS Iron/Stainless steel

-Higher design freedom due to its casting ability

-Better heat transfer

-Heat efficiency up to 108%

-Lower emissions to the atmosphere

-More energy-saving

-Lighter material and more durable

Condensing heat exchanger boilers of stainless steel and cast aluminum are close in efficiency, and cast iron boilers are less efficient than non-condensing heat exchanger. The design of the stainless steel boiler is limited. It can only rely on forming and welding. The water channel is in the shape of a spiral tube. Now some aluminum casting have improved processes, and thin-walled ones with longer lengths can also be cast as a whole. Aluminum has excellent thermal conductivity, its melting point is twice lower than that of cast iron, and its thermal conductivity is 10 times that of stainless steel. The durability of cast aluminum is better. The disadvantage of cast iron is that it is not as good as cast aluminum, and it is easy to crack and damage.

Compared with non-condensing boilers, condensing boilers can generally save more than 50% energy, and our design is more than 15% more energy efficient than other condensing design data (this data comes from the statistical data comparison of some customers of Yinnuo. There are also data showing that our design can be started at low gas pressure, while other Boiler cannot reach.)

Click to see more>> https://www.jjfoundry.com/condensing-heat-exchanger